Steel Pipes Vs. Steel Tubes

Table of Contents

introduction

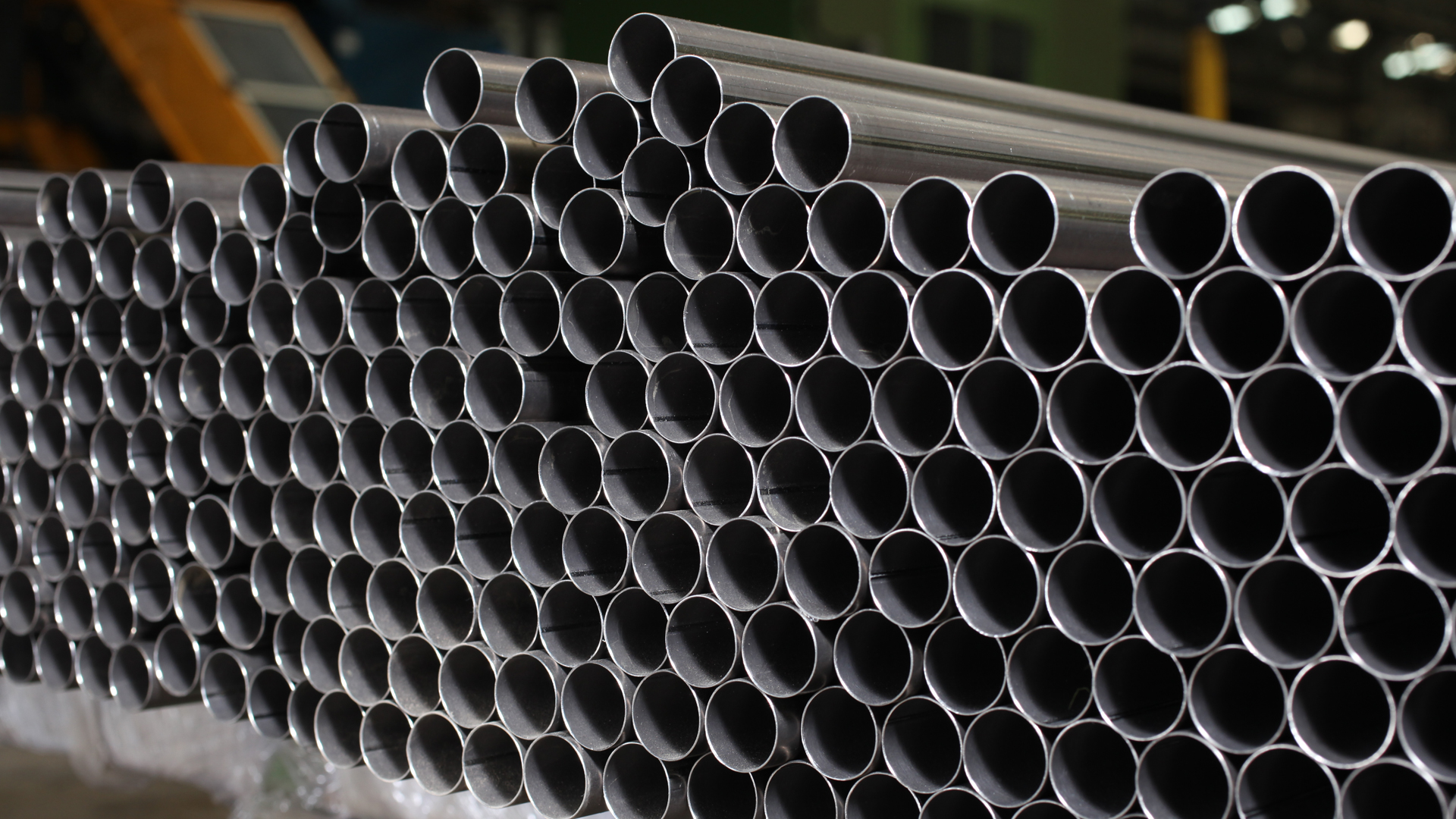

Steel tubes, tubing, and pipes perform important functions in many industries and act as vital components in many applications. These cylindrical steel constructions are vital in industries such as building, manufacturing, infrastructure, and transportation because of their outstanding strength, durability, and flexibility. Steel tubes, tubing, and pipes are made using an innovative manufacturing procedure. It frequently starts with the selection of high-quality steel alloys with excellent mechanical qualities, corrosion resistance, and the ability to tolerate significant temperatures. After that, these alloys are shaped into seamless or welded tubes using methods like extrusion, piercing, or rolling.

Steel Pipes

Steel pipes are long-lasting and durable pipes made of iron and other metals such as aluminum or manganese. They are seamless or may be welded along the length of the pipe. For protection against corrosion, they are zinc-coated using a hot zinc bath or an electroplating method. Zinc is suitable for coating water pipes since it is non-toxic to people.

Steel pipes are commonly used in water and gas transmission. Sizes range from 3/8 inch to 2 inch for these items. Working with steel pipes can be tricky, they must be threaded. Steel, despite its strength, may corrode over time. This happens when the zinc coating on the inside of the pipe wears away due to constant contact with water, leading to rust. They have an average lifespan of 50 years.

Steel Tubes

Hollow parts that can be circular, square, rectangular, or oval in shape are referred to as tubing. They serve a variety of functions, including mechanical applications, instrumentation systems, and pressure apparatus. Steel tube is formed from several materials such as iron, carbon, manganese, vanadium, and zirconium. Like pipes, tubing may be produced in two ways: seamless or welded. Rolling a solid piece of steel into a circular shape produces a seamless tube. After that, it is perforated and stretched to its ultimate length. Consider making a cylinder out of play dough and lengthening it by inserting your finger into the center. However, this technique is performed by machines that employ heat and spinning.

Steel Pipe and Tube Applications in Construction

Steel pipes and tubes are utilized in a variety of building projects. These examples represent a few of the applications:

Transmission Infrastructure: Overhead and overland transmission lines are supported by tubular and lattice poles composed of steel pipes and tubes. They’re used as well in trains, trams, and lighting fixtures.

Temporary Structures: They are used to create temporary structures such as halls, sheds, temporary bridges, motorways, railways, spectator stands, podiums, and other similar projects.

Roof Construction: Steel pipes and tubes are used in the roof construction of halls and stadiums to give structural support and stability.

Balconies and Railings: They are used to ensure the safety and longevity of balconies and stair railings.

Support Structures and Scaffoldings: Steel pipes and tubes are utilized during the construction process to produce supporting structures and scaffoldings, which give stability and strength.

Foundation Support: Steel tube piles are used for foundation support in building projects where the foundation is unstable or must withstand massive loads. These piles provide substantial support and stability to the constructions.

Construction Tools and Equipment: Ladders, shelves, and work tables are just a few examples of the tools and equipment made of steel pipes and tubes that offer productive and secure working conditions.

Pipeline Construction: Seamless steel pipes are frequently used in pipeline construction to transport items such as oil, water, and natural gas.

The Difference Between Pipe and Tube Diameter

- Steel pipes are made from a single metal piece, whereas steel tubes are made by welding many metal parts together.

- Steel pipes are typically utilized for fluid or gas transfer, whereas steel tubes are frequently used for structural purposes.

- Steel pipes come in a range of sizes, whereas steel tubes are often smaller.

- Steel pipes are sometimes more costly than steel tubes.

- Steel pipes are more likely to leak than steel tubes.

- Steel tubes are more prone than steel pipes to collapse.

Pipe and Tube Manufacturing Process

Tubes, like pipes, can be manufactured in two ways: seamless or welded. Making tubes is a little harder since the size and shape restrictions are more tight. Manufacturers have to ensure that the tubes meet the criteria or specifications that have been specified. Because tubes are a completed product, several elements must be considered during the process of production. This involves checking and testing the tubes to confirm their quality and looking for any defects or irregularities.

Furthermore, testing is performed to guarantee that the tubes satisfy the prescribed criteria.

Conclusion

The main difference between pipes and tubes is that while tubes are created by joining many metal parts together, pipes are constructed from a single metal piece. While pipes are frequently utilized in the conveyance of fluids and gases, tubes can be used in structural applications. Pipes have a wider diameter and cost more than tubes. Tubes are more likely to collapse than pipes, which are more likely to leak. The main building elements in many applications are steel pipes and tubes because they offer strength, durability, and dependability. They play crucial roles in the creation of infrastructure and aid in ensuring the general functionality and safety of building projects.